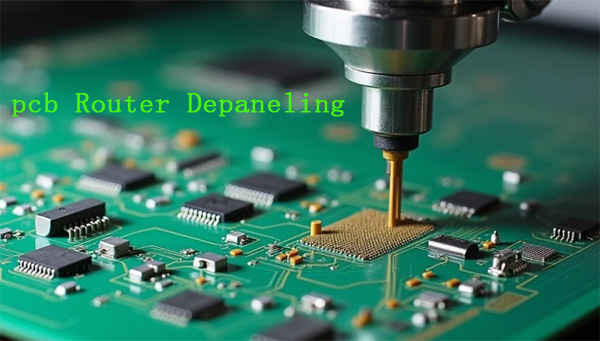

In electronics manufacturing, circuit boards are often made in large panels and then separated into smaller pieces. This process is called depaneling. Router depaneling uses a fast-spinning cutting tool, controlled by a machine, to carefully cut each board out. It gives smooth edges and avoids damage to small or delicate parts on the board. This method is better than older ways like snapping or V-scoring because it is more gentle and more accurate, especially for complex or crowded boards.As a professional with over ten years of experience in the PCB depaneling industry, I will explain the definition and working principle of router depaneling in this article, as well as the scenarios where it is most suitable.

What is PCB router depaneling?

PCB router depaneling is a highly precise and efficient method used in electronics manufacturing to separate individual PCBs from a larger panel after assembly.This process utilizes a specialized CNC-like router equipped with a high-speed spindle and a fine cutting bit to carefully slice through the predefined breakaway tabs or perforations that hold the boards together.

Unlike manual snapping or V-scoring, router depaneling ensures clean, smooth edges with minimal stress on sensitive components, making it ideal for densely populated or complex PCB designs.By automating the separation process, PCB router depaneling reduces the risk of damage while maintaining high throughput, offering a superior alternative to laser cutting or punching for rigid PCBs requiring tight tolerances.

What are the advantages of using router depaneling for PCBs?

●Precision Cutting – The CNC-controlled router makes extremely accurate cuts, ideal for complex board shapes and tight tolerances.

●Minimal Stress – Unlike manual breaking or punching, the smooth cutting motion reduces mechanical stress on sensitive components (like BGAs or small chips).

●Clean Edges – Leaves smooth, burr-free edges without rough fractures (common in V-scoring or snap-off methods).

●Flexibility – Can handle intricate designs, unusual board shapes, and densely populated PCBs without issue.

●Speed & Efficiency – Faster than laser depaneling for rigid boards, with no thermal damage risk.

●Automation-Friendly – Easily integrated into production lines for consistent, high-volume depaneling.

●Cost-Effective – Lower operational costs than laser systems while maintaining high quality.

What are the disadvantages of router depaneling?

●Dust & Debris – The cutting process creates fine dust, requiring cleanup and extra ventilation.

●Noise & Vibration – Routers can be loud and cause slight vibrations, which may affect sensitive components if not controlled.

●Wear & Tear – Cutting bits dull over time and need regular replacement, adding maintenance costs.

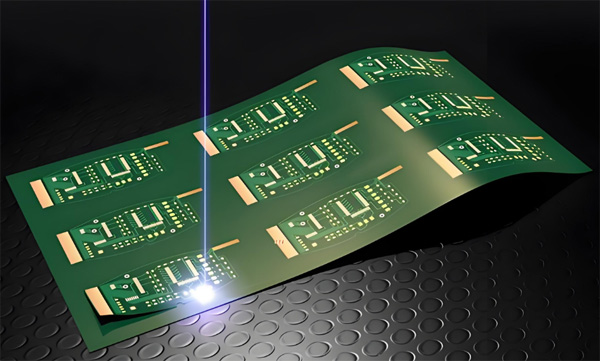

●Limited for Thin/Flexible Boards – Works best for rigid PCBs; thin or flex boards may bend or tear.

●Slower Than Punching – Not as fast as punch depaneling for simple, standardized panels.

●Upfront Cost – High-quality router machines are expensive compared to manual or V-score methods.

In which scenarios is router depaneling most suitable?

●Complex PCB Designs – Ideal for irregular shapes, tight tolerances, or intricate breakout tabs where precision is critical.

●Densely Populated Boards – Protects fragile components (BGAs, QFNs) by minimizing stress vs. snapping or punching.

●Rigid PCBs – Best for thicker, standard FR4 boards (not thin/flexible circuits prone to bending).

●High-Volume Production – Balances speed and accuracy for automated lines (faster than lasers for rigid panels).

●Clean Edge Requirements – Needed for applications like medical/aerospace where smooth edges prevent debris risks.

●Mixed-Panel Designs – Handles panels with multiple PCB variants in one array (unlike punch tools, which need uniformity).

Seprays’PCB router Depaneling Solutions

GAM 336AT In-Line Automatic PCB Router Depaneling Machine

GAM336AT In-Line Automatic PCB Router Depaneling Machine streamlines PCBA handling with 0-180° flexibility, ensuring compatibility across various production stages.

GAM 380AT Gripper In-Line Automatic PCB Bottom Depaneling Machine

The GAM 380AT Gripper In-Line Automatic PCB Bottom Depaneling Machine from SEPRAYS is a high-precision, versatile solution engineered for the efficient and accurate depaneling of printed circuit boards (PCBs).

Conclusion

Router depaneling is a smart and reliable way to separate PCBs, especially when clean cuts and protection of parts are important. It is great for complex shapes, thick boards, and large production runs. While it does make some dust and needs tool changes over time, its speed and quality make it a top choice in many factories. Machines like Seprays’ GAM 336AT and GAM 380AT help companies depanel quickly and accurately for today’s advanced electronics.

A professional with over a decade of experience in the PCB depaneling industry.