In PCB manufacturing, speed and cost matter. Punching depaneling is a quick way to cut individual PCBs from large panels. It uses a metal mold and press machine to punch out boards fast. This method works best for simple, high-volume PCB designs. While the mold costs money upfront, it saves time and money for big production runs. Many electronics makers use this method to make lots of boards quickly. As a professional with more than ten years of experience in the PCB depaneling industry, I will explain in this article the definition and working principle of punching depaneling, as well as the scenarios where it is most suitable.

What is punching depaneling in PCB manufacturing?

Punching depaneling quickly separates PCBs from panels using a custom punch press. Ideal for simple, high-volume rigid boards, it’s fast and cost-effective but requires expensive tooling and suits only basic shapes. Cleaner and faster than routing or laser cutting, it’s common in consumer electronics manufacturing.

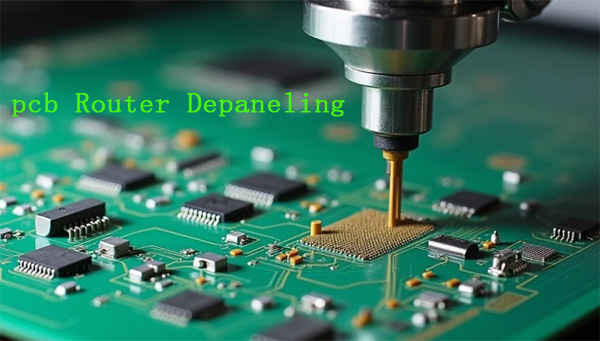

How does punching depaneling work?

Punching depaneling is a fast way to separate individual PCBs or FPCs from a larger panel using a special metal die and a press machine. First, a custom die is made to match the shape and layout of the PCB. Then, the panel is placed onto the lower part of the die. The panel must be aligned carefully so the die lines up with the edges of the boards. After that, a press machine pushes the upper die down with strong force, cutting the boards out—similar to using a cookie cutter. Once the boards are separated, they are either picked up by hand or removed automatically for the next step in production.

In which scenarios is punching depaneling most suitable?

●Large Production Runs

Punching is great for making many PCBs quickly and with the same quality.

●Stable Designs

If your PCB design doesn’t change often, punching is cost-effective because making the die is expensive.

●Simple Board Shapes

Punching works best for boards with straight or simple shapes, not very detailed or weird shapes.

●Fast Production Needs

This method is very fast, so it’s good when you need to produce lots of boards quickly.

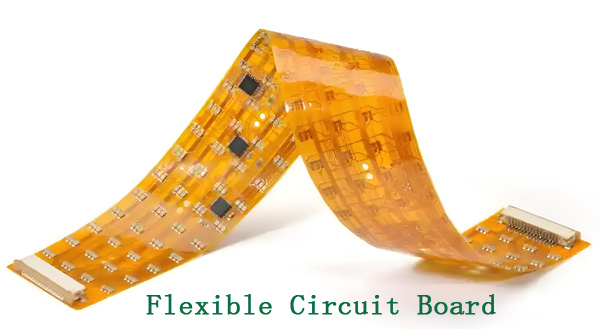

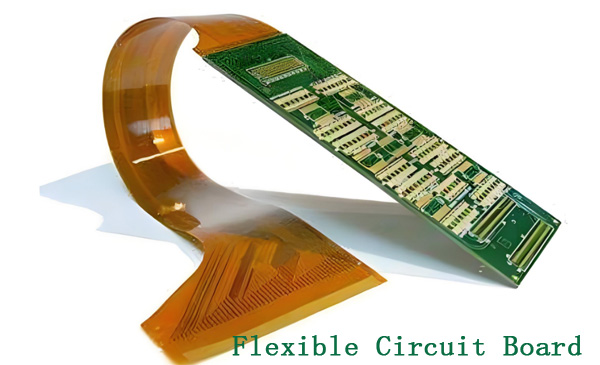

●Rigid and Flexible Boards

Punching can be used on both stiff PCBs and flexible circuits.

●Lower Cost per Board

After the die is made, punching is cheap for each board, which saves money in big batches.

Seprays’Punching Depaneling Solutions

ZM10T/ 15T PCB/FPC Punching Cutting Machine

The ZM10T/15T PCB & FPC Punching Cutting Machine is a highly efficient and advanced solution for the precision processing of Flexible Printed Circuits (FPCs) and Printed Circuit Board Assemblies (PCBAs).

ZM10TS / 15TS PCB/FPC Punching Cutting Machine

The ZM10TS / 15TS PCB & FPC Punching Cutting Machine with a focus on delivering high-performance punching and cutting solutions for Flexible Printed Circuits (FPCs) and Printed Circuit Board Assemblies (PCBAs).

Conclusion

Punching depaneling is a great choice when you need to make many PCBs fast and cheap. It’s perfect for simple board designs and large orders. Machines like Seprays’ ZM10T/15T make the process even easier. If you need to produce lots of boards without high costs, punching depaneling is a smart solution.

A professional with over a decade of experience in the PCB depaneling industry.