Features

-

Flexible Single Transfer with 0–180° Rotation:

The system features a flexible single transfer arm that can pick and place PCBA at angles from 0 to 180 degrees, accommodating the needs of both upstream and downstream processes.

-

CCD Vision Positioning and Alignment:

A built-in CCD vision system provides precise offset correction and alignment, ensuring high cutting accuracy during the depaneling process.

-

High-Speed ESD-Protected Spindle with Auto Tool-Change:

Equipped with an electrostatic discharge (ESD) safe spindle, capable of automatic tool changes, this reduces the risk of static damage to sensitive PCBA components.

-

Patented Flexible Brush for Router Bit Extension:

A patented flexible brush design allows the router bit’s blade to be split into multiple working sections, effectively prolonging the tool’s service life.

-

Multiple Product Unloading Options:

Supports three unloading methods:

-

Belt conveyor,

-

Fixture unloading, or

-

Custom tray placement, offering flexible solutions based on production needs.

-

-

Dual Spindle High-Efficiency Models Available:

Additional high-efficiency configurations are available, such as model GAM336AD and GAM336ALD, which feature dual spindles for enhanced throughput and customer-specific applications.

Optional

- Cutting detection module

- The height checking module in laser

- Barcode reader

- Milling tool diameter detection

- The customized MES

Look no further! The same machines used by the world’s top 500companies

More than one thousand well-known enterprises chose Seprays separator and established long-term cooperation.

Send us a direct message now, just send us a picture of your product and we’ll be able to recommend the right product for you immediately.

Product Parameters

| Model | GAM336AT |

|---|---|

| Valid cutting size | 450*420mm |

| Loading method | Track delivery |

| Unloading method | Conveyor belt or track delivery |

| Movement direction | Left to right or right to left |

| Cutting function | Tweening to staight line, L shape, U shape Circle, Arc |

| Process table | Dual tables |

| Repeat precision | ±0.01mm |

| Cutting precision | ±0.05mm |

| Max moving speed | XY: 1000mm/sec, Z: 800mm/sec |

| Spindle’s speed | MAX: 60000rpm (Adjustable) |

| Tool change type | Auto tool change |

| Safety protection | Sefety light curtain |

| Cutting speed | 1-100mm/s |

| Operating system | Windows10 |

| Program teaching method | Intuitive teaching by CCD color image input |

| Control method | Precision multi-axis control system |

| XYZ axis driving mode | AC Servo motor |

| Size of milling tool | 0.8-3.0mm |

| Voltage/Power requirement | AC220V 50/60Hz 4KW Single-phase |

| Pneumatic pressure requirement | 0.6MPa, 220L/min |

| Dimensions(W*D*H) | 1947*2096*1820mm |

| Weight | 1145kg |

| Dust collector | TS300L |

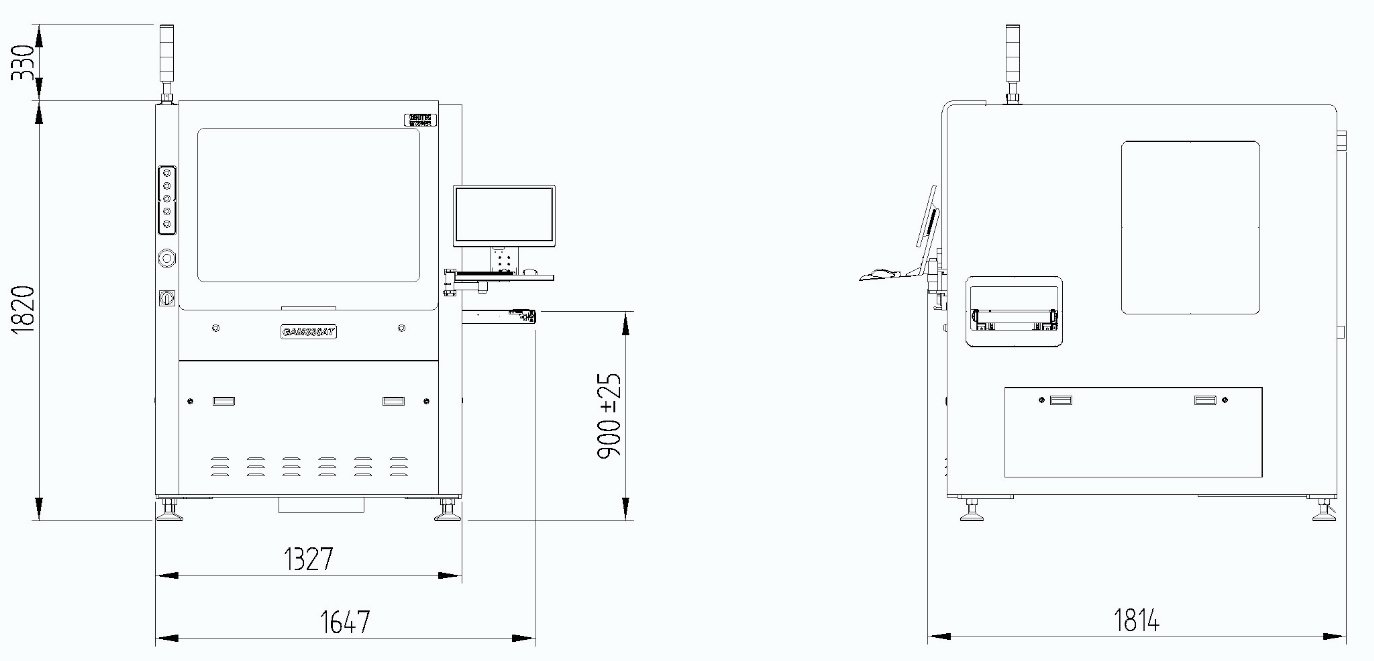

Front View/Side View